Maybe you could rig something up with retractable badge holders. You might be able to get them for free from your work.

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

Yes, something like this I was thinking about. A boom arm or pole or something like that would then reach over the printer and the retractable badge holders could hold the cables and feed tube up without interfering with them that much.

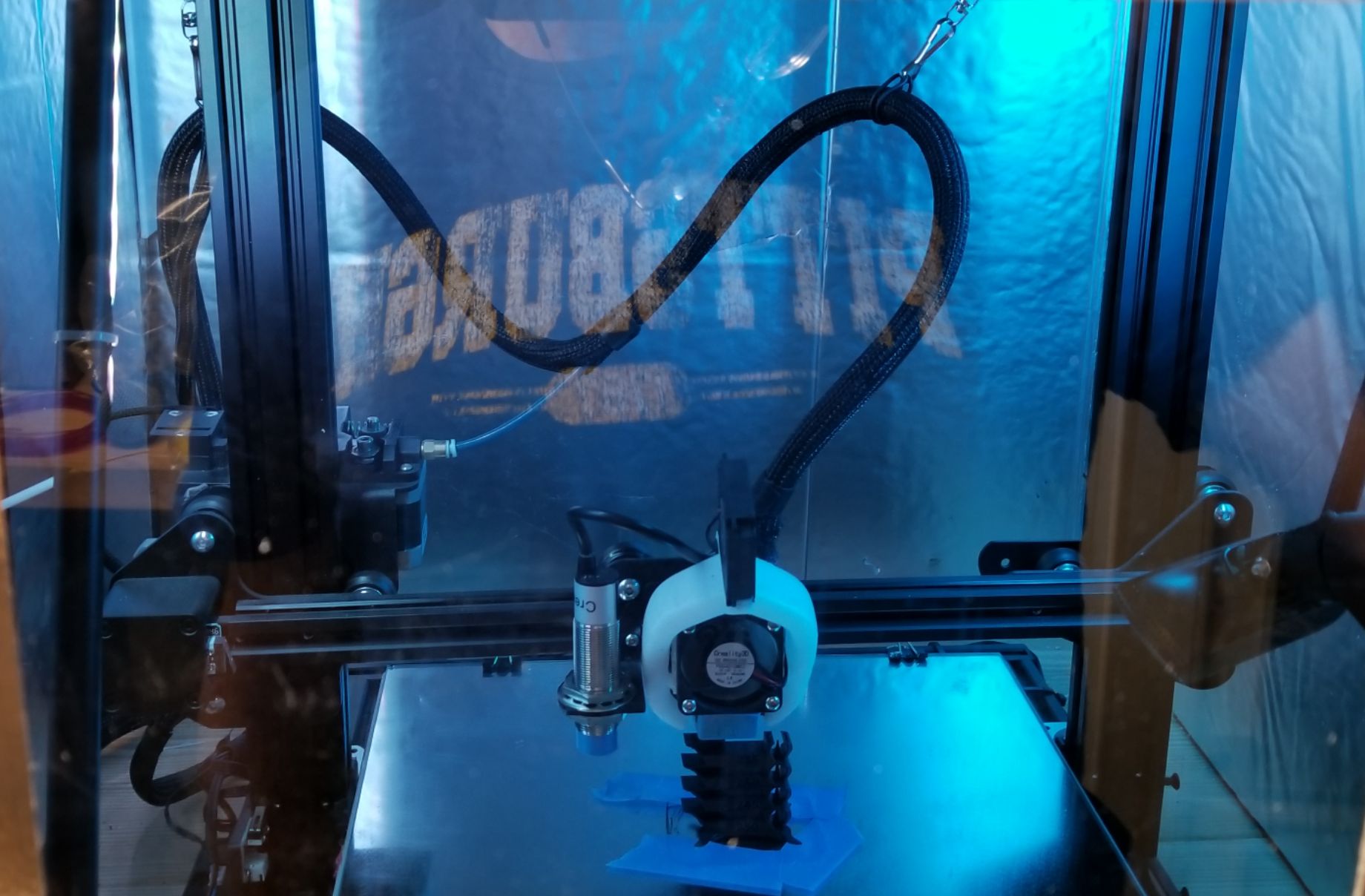

This is exactly what I do. I had a couple retractable cables let over from my wired-VR days and rigged it up on my CR10s. Works great. Here's a pic - they tops are just connected to the top rail with a rubber band for easy removal. (this was take through the "window" in my enclosure, so you can't see the top)

I would suggest zip ties and rerouting/moving the filament feed tube to be ran along with the wires. Generally, when snuggly bundled the lot becomes stiff enough to keep it free.

Otherwise cable chains- but with a system that moves in x and why, you will have to chain to the x slide and then the y slide to see any real benefit- they’re supposed to roll on a single axis…. And this would considerably increase the length of the over all run.

I specifically moved the filament feed tube to the front so that the whole thing is more accessible and easier to handle, by default the whole stuff is at the end but I found it too annoying to always have to grab/reach through my printer under the bed to do anything with the filament.

I did try using a spare PTFE tube for the cables but this didn't really help that much. But I must say, I have fewer issues with the cables, the filament feed tube is more of an issue I want to address.

Two options:

1.GFK road as a stiffener.

- Energychain/dragchain.

If you want it simple and cheap use the GFK. Otherwise, opt for the drag chain. If you need help selecting the chain feel free to ask. Btw. Upgrade to the Biqu CAN hotend/adapter and use a single can-bus/fieldbus cable.

You might be interested in a cable cable chain like this:

https://www.thingiverse.com/thing:5251511

I printed one for my Ender 3 v2, and it works flawlessly for mitigating the issues you described.

Yeah, I have seen this and played with that Idea for a while but never really could find something that would fit or work with how my setup is constructed. Since I have an Exoslide, custom shroud and so on, those Cable Chains are mostly designed for stock parts.

And I am by far not skilled enough to make the adjustments or remix those things myself.

TL;DR No.

short version: No. Bad design.

longer version: Drag chains 101: defined bending radius, no overlapping cables, and strain relief on both ends. This design has none of those properties.

very long version: Read up on energy chains.

Great points. I appreciate the critique. Can you recommend a design that ameliorates the issues you mentioned?

I make my own when I need them, so I am not aware of good models for the Ender 5. With the points mentioned, I think you could tell whether a chain is good or not.

Quick search. This looks promising: https://www.thingiverse.com/thing:4635454

This is the interface/linking I use. One detail that isn't visible: the "hub" isn't a cylinder. It's a truncated cone.

end pice:

Thank you so much for this. I definitely have a better idea of what to look for. I see exactly what you mean regarding the linkage. I have yet to see that system for limiting the radial movement. I love the elegant simplicity. I haven't had any problems with my current chain, but I will definitely incorporate these elements into the next chain I print.

I was gonna print one of these chains, what would be a good design?

Disclaimer: I have zero experience with 3D printing.

With that said, I'd think better cable management and zip ties in the right places might help.

Other than that, I'm not sure if anyone can give you good solid advice without seeing photos/video of your current setup.

Thanks, I added an image link to the original post.

As awesomely helpful as that should be, the image isn't loading for me. I dunno, might just be a thing on my end.. 🤷♂️

Anyways, best of luck there, I see someone else suggested a cable chain setup that just might do the trick.