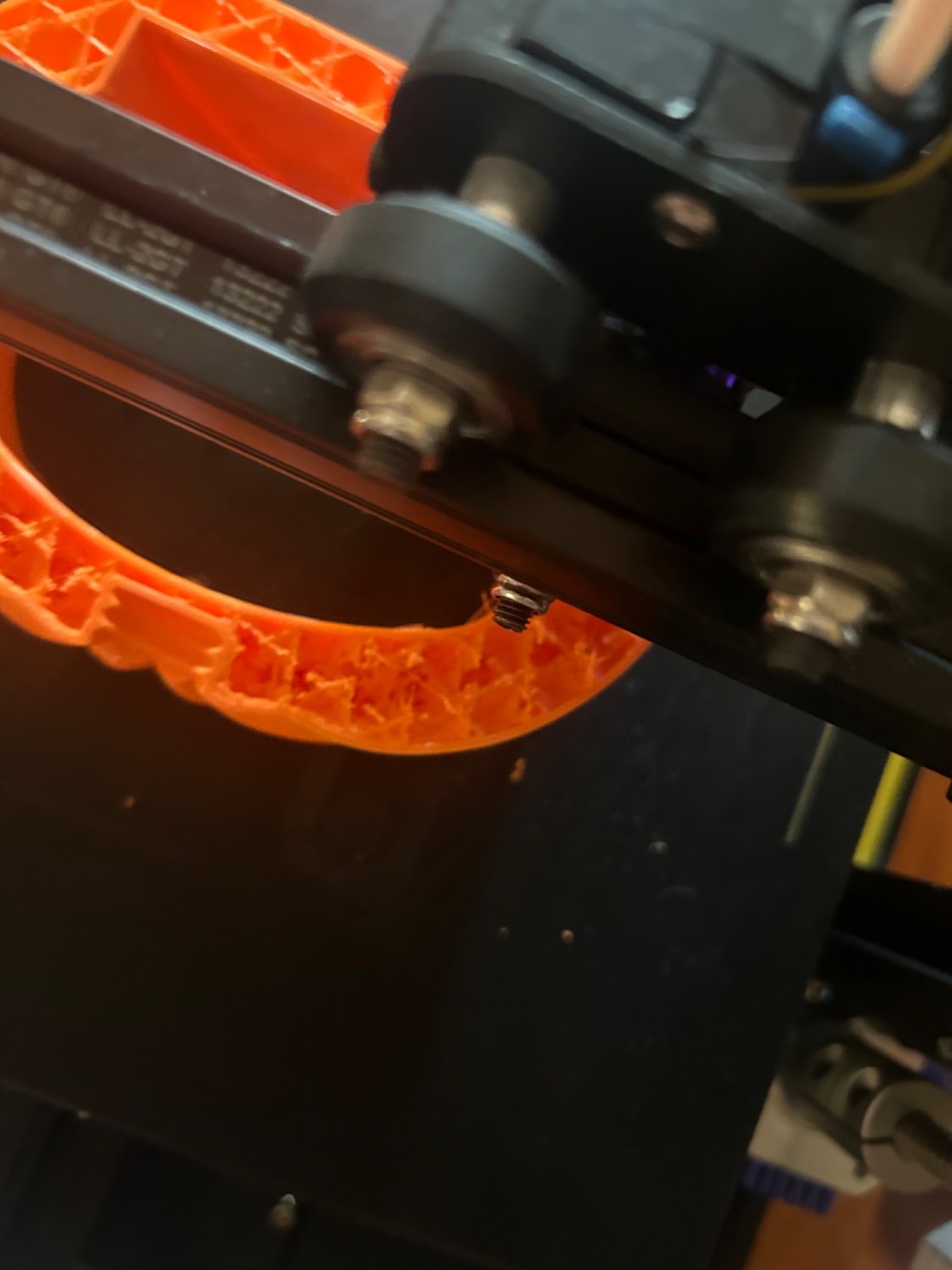

Is that petg? For some reason I usually have problems with petg and infill patterns that cross over itself so I usually switch to gyroid. I think it has something to do with the speed and flow and the properties of the filament that make it especially bad when the infill lines cross over itself. You can probably tune temps, speeds, and feeds to get it to work but I find it easier to just not use that infill pattern.

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

It is PETG. That’s good to know. I’ve got a few more prints on the docket so switch to gyroid and see how that goes. Thanks for the tip!

I also have issues like what you're having when I'm printing with PETG, and using gyroid infill pattern eliminates it completely for me.

If you haven't yet, try a cold pull and see if that helps. I personally just do a cold pull every time I change filaments. Maybe it helps, maybe it's overkill, but I rarely have issues around clogs.

Other things to think about:

- Does this happen with other filaments? Maybe your current filament is wet and needs drying. Maybe you just got a bad batch.

- Does slowing down the print speed for infill make a difference? Perhaps this filament is just flowing differently and you need to change the printing temperature, flow rate, or just slow down.

- How old is your nozzle? They do wear out and a worn out nozzle can manifest as all kinds of wonky problems.

Thanks for the other tips. I’ve tried a cold pole with the last filament to see if we could get anything out of there and I think we should be good, but you never really know.

As far as the rest of it, it seems to be happening with every filament I slice in Prusa slicer.

This was a brand new filament I had opened from Micro Center, it’s just their generic inland filament and it looks like the humidity in my dry box is about 16% after running it through my dryer. Maybe it’s too dry lol.

To be honest, I didn’t think about replacing the nozzle that’s probably a good idea. I got this printer from an auction site used so I can only imagine it’s the original nozzle from who knows how long ago

As far as the rest of it, it seems to be happening with every filament I slice in Prusa slicer.

This just reminded me of an issue I was facing recently. I also use Prusa Slicer and was having a hell of a time with my prints. It turned out to be the "Arc Fitting" setting.

In Print Settings - Advanced - Slicing look for the *Arc Fitting setting. When I had it set to "Enabled: G2/3IJ" it just completely borked my prints. Just weird problems all over the place. As soon as I set that to "Disabled", it cleaned up my prints considerably. Not sure exactly what I'm giving up there, but I do know I'm getting much better prints.

Thank you for the tip! I just checked, it looks like it was disabled so that wasn’t my issue. I wonder why it was causing you issues though

Maybe try adjusting flow rate and/or speed for infill in the slicer?

Good call I’ll have to take a look. I wish I could’ve copied the profile from the Creality slicer into Prusa Slicer, but creality keeps crashing.

whats the speed difference between your walls and infill?

I’ll have to go back and look at the slicer settings, but I can tell you the info is much faster than the wall just watching it go. Would you recommend upping the flow rate or my better to slow down the printhead speed?

It looks like my perimeter speed is 40 mms and my infill is 50mms

Is that a Tronxy?

Nope, just a very moody Ender 3v2 Neo