Hello :).

I have some of these Molex 1054440011 USB-C edge connectors/plugs of that I somehow don’t know what’s the best way to assemble them onto my PCB.

I have the pads (standard layout from the datasheet drawing) exposed on the stencil but the pins push the paste away a little so I had quite an amount of solder bridges to rework after reflowing them. Could probably a little less solder paste (so smaller openings) and/or differently shaped stencil openings help? Also there are pins (and other components) on the backside so it’s difficult to apply paste accurately on both sides.

The pins are additionally a little weirdly shaped (they bend upwards at the ends so it’s easier to push the PCB between the pins) what makes them less accessible with a soldering iron and the 0.5mm pitch doesn’t make things easier. At least the tension of the pins holds the connector in place while reflowing.

This specific one will primarily only be a one (or two)-off prototype board so I could life with some reworking but maybe someone around here has experience with these things. I also wondered how something like that would be assembled in a larger scale, the pins hold the PCB quite tight between them, I can’t imagine a pick-and-place machine could handle that.

Thanks for reading this post and maybe you have some answers :).

I’ll give that a try, I was a little afraid to bend the pins of the connector but they seem really strong compared to regular QFP pins. I did also order some gel-like flux which seems, according to the videos I found, to work way better than the liquid one I have.

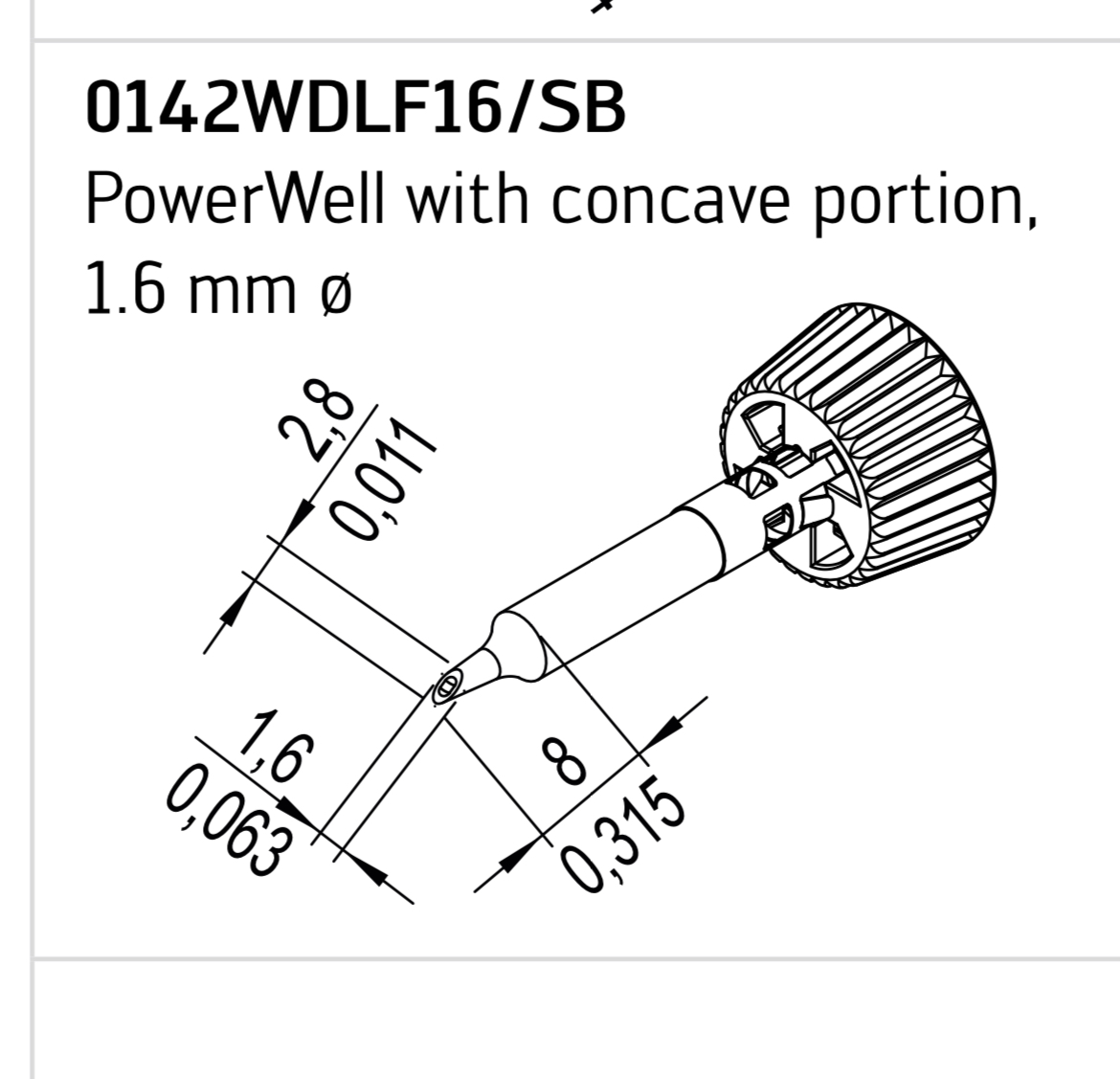

Does a regular chisel tip work good or should I better get something like this with an concave tip?

that's a good question--I've always just gotten the concave chisel tip because they're the same price and I didn't see any drawbacks to it under any circumstances.

I do tend to do a lot of work like this with K-tips, and those don't have a cup. I imagine that the non-concave tip would work ok. I would give it a try with your current equipment, and then think about getting a new tip if you end up doing this more.

I just received that gel-flux I ordered and gave it a try on some cheaper boards I got to practice :D. I did mess up one but the second one actually did come out pretty okay and wasn’t too much of an issue:

There's not enough pixels to really check for issues, but it looks very neat! Nice work!