3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

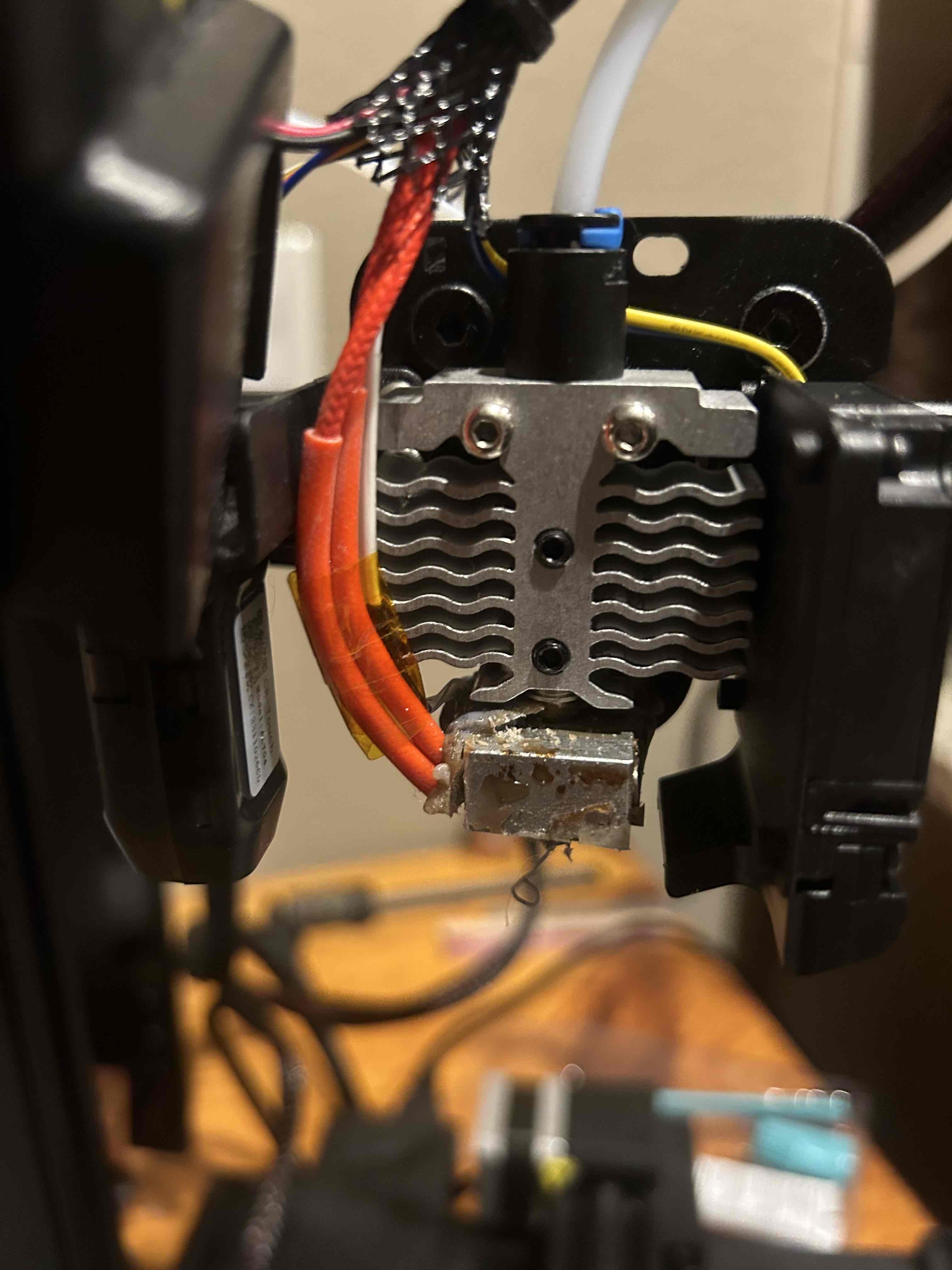

As people have said already this is a somewhat common failure mode, especially when swapping nozzles. This happened to me twice between three nozzle swaps. The first time was a major leak like yours, the other time it was only slight (which I then made worse in my attempt to fix...). I was obviously doing something wrong, but I came fully prepared the second time with video guides for my specific machine and everything but still couldn't get it perfect.

If you never want to think about this failure mode again (like me) then consider swapping your hotend for a Revo. A Revo nozzle is also the heatbreak, so there's no possibility of a bad connection between them. The 'nozzles' are more expensive but they can be hotswapped (coldswapped, even) by hand with no special tools. Before I did everything in my power to avoid nozzle swaps, so I ended up settling for a jack-of-all-trades (but master of none) nozzle that I would never have to swap. Since moving to Revo however I find myself swapping nozzles way more now that it's easy and with no chance of destroying my hotend. For instance I have a high-flow 1mm nozzle for quickly doing big structural prints, they print in like one third of the time and are way stronger than equivalent prints on a smaller nozzle. I also have a 0.25mm nozzle for miniature model prints with a better resolution than I could ever get before. I'm still waiting for a high-flow abrasion-resistant Revo nozzle, though.

Thank you for the tip! I’ll look into those for sure. It sounds like they would be a perfect fit with very little downside