3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

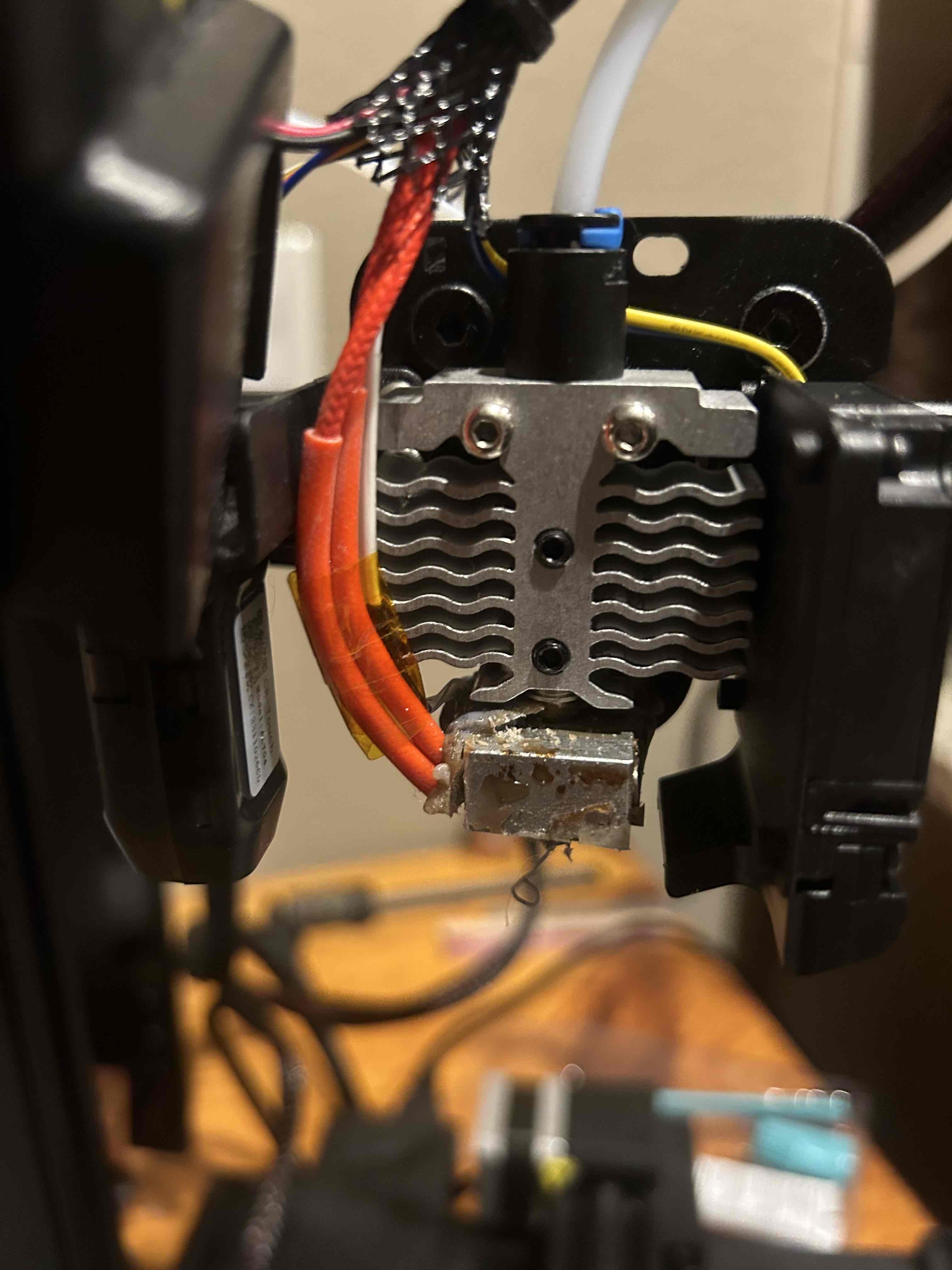

I’m guessing you have a nozzle not screwed in fully, or there was filament above the threads preventing it from seating. I’d warm the print head, remove the nozzle, run a bit of filament through without the nozzle, then yank it out, hopefully pulling any globs down and out of the heater block. Reassemble hot and make sure the nozzle seats firmly. Good luck!

Thank you!

It's worth noting that some but not all combinations of heat break, nozzle, and heater block require re-tightening at the temperature used for printing. Basically, different metals expand different amounts when they're heated, so if the block expands more than the other two, a gap will open up between them, and melted filament can find its way through.

Good to know. I’ll add that to a check list to go through every now and again

Yes and on some printers, that spot where the Bowden tube meets the nozzle is very problematic. You have to loosen the nozzle a bit, push the Bowden tub up against it, then tighten the nozzle the rest of the way

It was awful on my Ender clone, but haven't had that issue on my Prusa.