this post was submitted on 25 Jul 2023

27 points (96.6% liked)

PC Master Race

14934 readers

1 users here now

A community for PC Master Race.

Rules:

- No bigotry: Including racism, sexism, homophobia, transphobia, or xenophobia. Code of Conduct.

- Be respectful. Everyone should feel welcome here.

- No NSFW content.

- No Ads / Spamming.

- Be thoughtful and helpful: even with ‘stupid’ questions. The world won’t be made better or worse by snarky comments schooling naive newcomers on Lemmy.

Notes:

- PCMR Community Name - Our Response and the Survey

founded 1 year ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

Is there any research about how this avoids air pockets?

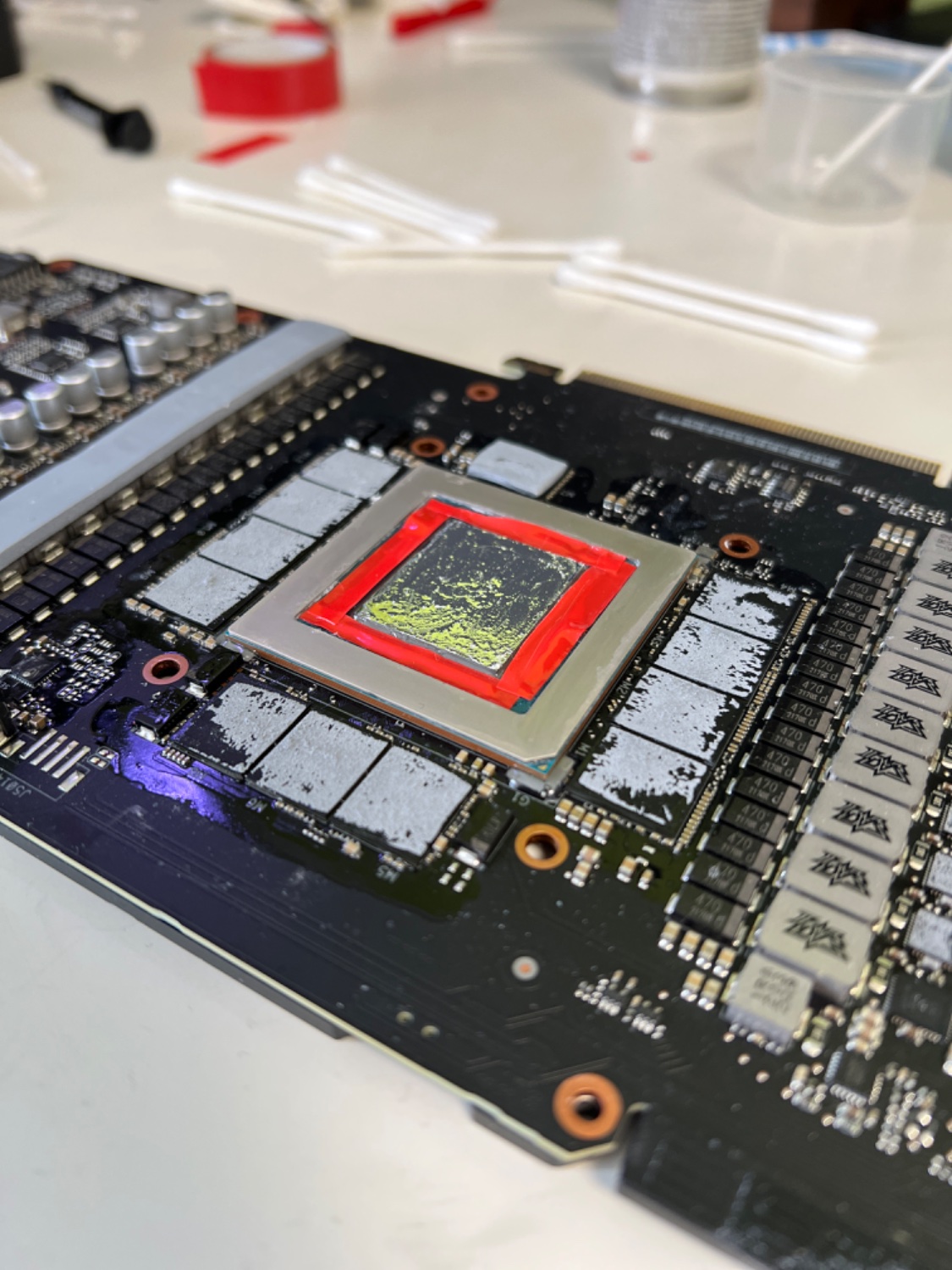

I'm curious how the "liquid metal" achieves 'wet' contact compared to a compound that can be applied in a way that pushes out air as it is compressed.

You are actually applying the thermal compound to the physical die. I don't know the structure on the silicon, and how they are integrating temperature management. Thermal contact consistency looks like it is super critical for this kind of package.

The only reference I found (in 5min of looking) about the die and packaging:

https://piped.video/watch?v=biEoBo8S0Zo

If anyone knows of content that goes deeper by removing the die and etching the layers with high resolution microscopy I would love to see this, or if anyone has deeper info about the "liquid metal" compound without any marketing nonsense, I'd like to see that too. I know Tech Ingredients on YT covered thermal compounds, but I don't recall anything about liquid metal.

The instructions stated to apply the LM to both the die and the cooler surface so that the two surfaces basically merge when you remount the cooler.

Temps are fine, so I assume there aren’t any air pockets